Landscape design

Lighting options for a country house and a summer cottage

Landscape design

Lighting options for a country house and a summer cottage

Concrete is a material consisting of a mixture of sand, gravel, cement and water. To strengthen the strength of concrete structures, they are additionally reinforced with metal reinforcement. In this case, the material is already called reinforced concrete. Both the first and second products are widely used in the construction of buildings and structures. The construction of fences around industrial and agricultural enterprises, civil and housing facilities was no exception.

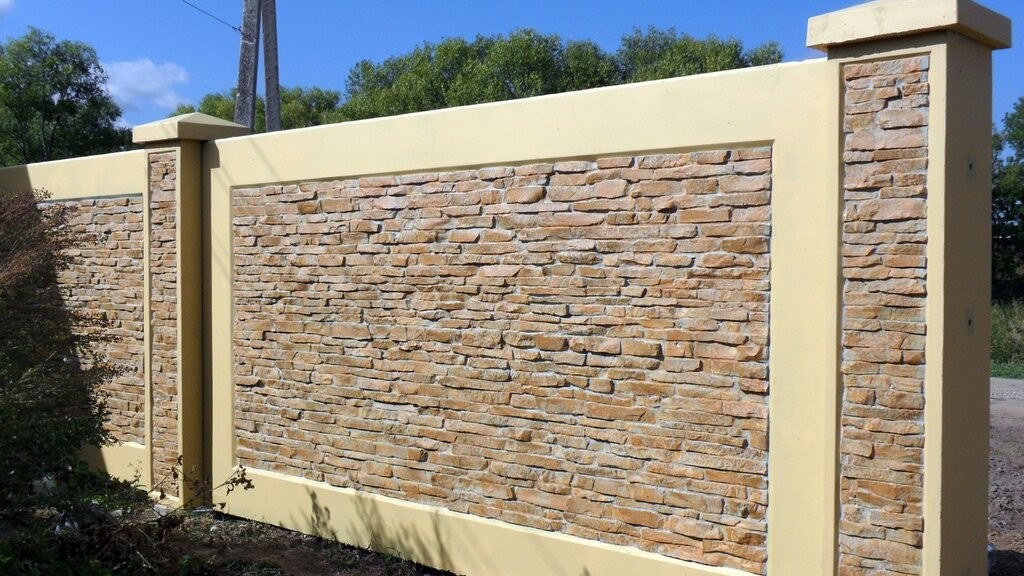

A modern reinforced concrete fence can look very attractive

Concrete fence as an element of decor

Content

The massive construction of individual cottages, country houses spurred engineering in the direction of the design of fences. The introduction of modern technologies, the emergence of non-ferrous cements, made it possible to put the production of reinforced concrete fences on the stream and even introduce decor elements into their device.

There is no arguing that the concrete fence is one of the most reliable structures

Such a fence will stand for many years, subject to proper calculation and high-quality installation

The choice of the external design of the concrete fence around the land now depends only on the preferences of the owner and his financial capabilities. The flight of ideas here is unlimited. You can order an original project for an individual order, or you can limit yourself to simple, but expressive in artistic terms, elements of the fence.

Types of concrete fences

There are various variations of concrete fencing

Monolithic fence

A monolithic barrier allows you to completely protect the enclosed space from indiscreet views, the noise of roads, the attacks of thieves.

Monolithic fences are erected at the installation site: the perimeter of the site. The material used is concrete and metal reinforcement. Concrete can be prepared at the construction site in a concrete mixer or ordered ready at the factory. In the latter case, the material is delivered in concrete mixer trucks equipped with special sleeves that facilitate the flow of the liquid mixture.

A monolithic concrete fence is cast directly on site

For casting, formwork is used, on which the appearance of the fence depends

For a monolithic fence, a concrete foundation is surely arranged. It can be continuous, tape or pile, when reinforced concrete grillage is laid on the heads of piles. The dimensions, deepening and reinforcement of the foundation depend on the dimensions of the monolithic fence and the criteria for its strength. In difficult cases, a design calculation may be required.

The main conditions for the construction of the foundation are sufficient penetration and a single design mark of the top of the foundation.

Monolithic concrete structures require accurate calculations

For all structural elements of a monolithic fence, the installation of a metal or wooden formwork is required. Reinforcing cages are laid in it and liquid concrete mix is poured. So that there are no shells and voids in the concrete, it is sealed with vibrators or pins. All components are fastened together with special iron anchors.

The main advantage of monolithic fences is the possibility of original architectural forms.

The strength of the fence depends on the selected concrete brand. After a set of concrete design capacity, the formwork is removed. In its original form, a fence made of monolithic concrete does not differ in high aesthetics. Stone finishing, decorative plastering and other decoration elements will help to give a finished decoration.

Finishing a concrete fence can be quite attractive, but it raises the cost of fencing

Monolithic sectional fence

Installation of fencing from monolithic reinforced concrete sections of factory manufacture is more mechanized, less time-consuming than the above described option of the fence. The tape concrete base is poured, which provides supports for mounting columns of monolithic sections. The deepening of the foundation depends on the type of soil and the weight of the reinforced concrete elements of the fence.

Installation of a monolithic section is carried out using equipment

A separate monolithic section consists of a fence panel and a support column on one side. The reinforced concrete pillar has a recess on the bottom for fastening to the foundation and a vertical groove on the side for connecting to an adjacent slab.

Typical sections come in different sizes, the cost of the product depends on the dimensions

Significant weight and dimensions of finished monolithic structures require special equipment for their transportation and installation. The process of building barriers from individual monolithic sections using a truck crane is only possible for professional builders.

Manufacturers produce reinforced concrete sections “brick-like”, “stone-like” or with geometric patterns

Factory concrete panels for the fence are distinguished by a variety of shapes and textured finishes. After installation in place, concrete structures can be ennobled with painting, decorative plaster or tiled.

Stacked Sectional Fences

The kit for the device of such a fence includes reinforced concrete elements made in the same style:

- poles with grooves for hanging individual parts of the fence;

- deaf enclosing sections;

- patterned decorative sections.

The designs of the typesetting fence are made at reinforced concrete enterprises using special vibration casting technology. The output is high-density products, characterized by a wide variety of textures and colors. Such fences are quite strong and durable.

The design is a small format slabs installed in the grooves of pillars of an H-shaped profile

Foundation is optional. Installation of a fence under the power of a team of several workers. The low weight of the sections (40-70 kg) can significantly save on transportation costs. The installation process of the fence begins with the installation of reinforced concrete pillars. The supports are spaced apart from one another, allowing the fence panels to freely enter the grooves of the posts.

The support pit is poured with concrete only after checking the horizontal installation of the lower section. The depth of embedment of the support posts can reach 1.5 meters.

The height of the fence depends on the number of sections mounted on each other. Typically, the number varies from 3 to 5 elements. Stacked fence made of panels is popular in individual construction. The artistic design of the structure must be taken care of at the stage of manufacturing the components. It is possible for modern technologies to make surfaces imitating wood, brick, stone. With this decor, an ordinary fence becomes a rich and prestigious decoration of a personal plot.

Assembled section of the fence may consist of blind or openwork elements

The bottom of the stacked fence (2-3 sections) is assembled from solid panels, the upper part has gaps, architectural decorations in the form of openwork concrete ornaments, balusters. The panels are finished on both sides or in an economical version only on the front side.

Concrete castings can have the most diverse form and texture.

A concrete stacked fence is much lighter and cheaper than similar monolithic structures. At the request of the owner of the territory, a stacked fence may consist entirely of deaf elements.

Monolithic reinforced concrete fence

Self-contained reinforced concrete slabs are often used to enclose large industrial enterprises and construction sites. Their installation does not require foundation laying and installation of poles. The support for these slabs is their massive lower part, the width of which reaches 110 cm. The large weight of the T-shaped sole shifts the center of gravity of the slab to the lower base and guarantees the stability of the concrete section.

Such fences are often used to create temporary fences.

The construction technology is as follows:

- Plates are installed on a flat, solid plane.

- In the case of installation on the ground, a shallow (15-20 cm) trench is dug wider than the base of the slab.

- Pour a mixture of sand with crushed stone and carefully tamp it.

- The plates are lowered onto the prepared pillow using a truck crane.

- Separate sections are joined together.

An independent fence can be removed at any time and moved to a new location. Such panels have a modest design. A distinctive feature of an independent fence of concrete sections is its high strength.

A striking example of a sectional fence is the famous reinforced concrete product PO-2 with rhombuses in sections

A variety of monolithic plates with racks below is produced. To them are reinforced concrete glasses-supports. Glasses are installed around the perimeter of the fence at a distance depending on the length of the slab. The monolithic section is lowered so that the lower spikes of the slab enter the bowl capacity.

Block concrete fence

There is a huge variety of ready-made concrete blocks for the assembly of this type of fence. Elements can be monolithic or lightweight - hollow. Unfinished and decorative. In the latter case, colored pigments are added to the composition of the concrete, forming a two-sided texture for brick, stone, rock. The standard size of the masonry unit is 20x20x40 cm.

The name of such a fence speaks for itself - a block fence, which means it is made of blocks

Traditionally, blocks are laid on a strip foundation, the width of which is two times the width of the block. Specialists advise to lower the bottom of the base below the level of soil freezing. The height of the fence is dictated by the preferences of the owner.

The foundation is calculated taking into account the size and weight of the selected blocks

Blocks are stacked vertically with ligation of vertical joints to enhance the strength of the structure. Fencing from conventional blocks requires additional decoration to cover the seams.

To strengthen the structure, hollow blocks can be stacked with vertical reinforcement

In addition to aesthetic appeal, block fences have many other advantages:

- simplicity of construction;

- reliability, durability;

- inexpensive price;

- the possibility of combining with other materials;

- a wide range of decorative finishes;

- many options for execution;

- the presence of internal sinuses for laying wires.

Combined fence on the base of concrete blocks and decorative sections made of metal

The disadvantages include:

- mandatory reinforced concrete foundation;

- the complexity of the work.

The combination of stone-lined concrete and wood at the top of the fence

Decorative sectional concrete fences

These include all fences, which, in addition to the function of fencing and protection, serve as decoration of the street and the site. Above we examined decorative typesetting fences, fences from ennobled concrete blocks. The components of such fences are made at reinforced concrete enterprises using vibrocasting technology with the decoration of external surfaces.

Precast concrete fence with decorative elements

Manufacturers have catalogs of products of various sizes, a wide color palette, a beautiful texture that creates the illusion of expensive natural coatings. The variety of forms and models for concrete casting allows you to create spatial, three-dimensional structures that differ in the original decor.

Stacked sectional fence “under the tree”

Designers create combined fences that harmoniously combine concrete elements with a wooden fence, cast-iron grating, forged products and other architectural decorations.

What to look for when choosing a fence

- Decide what purpose the fence is for.

- Pay attention to the appearance, size of the fence, the absence of defects.

- Check concrete grade and reinforcement of structures. Commonly used concrete mix grades 250-350.

- Buy from trusted, reliable manufacturers with accompanying documents.

- Take into account your financial capabilities.

- Try to establish practical care designs.

- Take into account labor costs, the possibility of self-installation or the need for special equipment.

- Trying to create a single style with the design of the house and land.

- Do not forget about durability, the fence should not stand for a month or two, but for many years.

Perform a design calculation if necessary.

A “purely” decorative fence is also made of concrete, which serves as a stylish decoration of a suburban area.

Useful video about painting a concrete fence